Honored to work with:

What is a Dust Collector?

Dust Collector (sometimes called Bag filter), also known as a baghouse filter, is one of the most important and efficient types of air and dust filtration devices, which due to the need to comply with environmental standards in factories and industrial centers. Also, in order to prevent the waste of the product produced in the factories and its distribution in the environment, as well as the observance of the physical and mental health of the workers, its use in many dusty environments is inevitable.

Different types of Dust Collector:

- Manual

- Mechanical

- Jet pulse

How does Dust Collectors work?

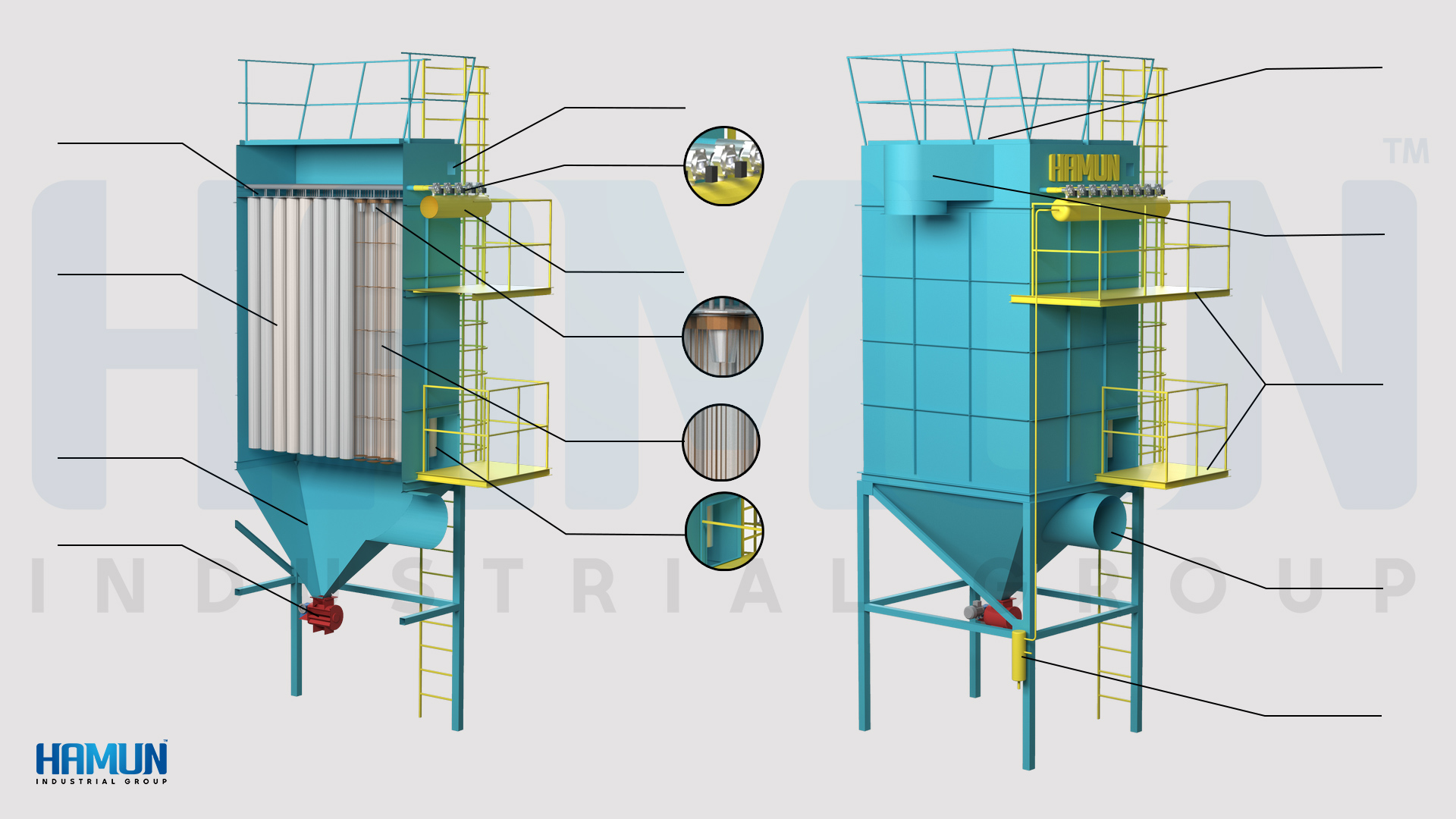

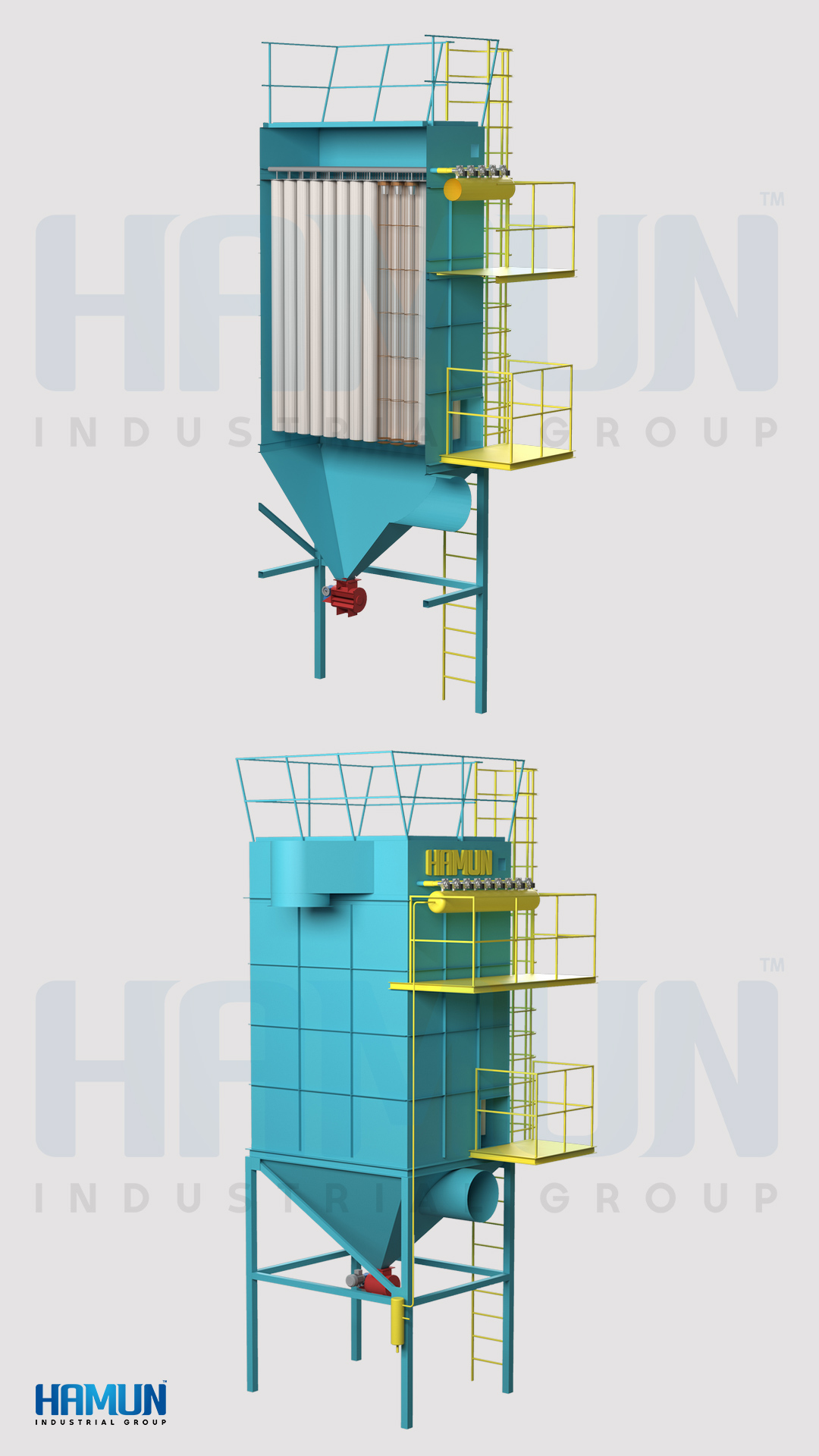

Dust Collector consist of cubic and sometimes cylindrical chambers with a funnel at the bottom with a slope of about 60 degrees. Fabric filters are placed inside the cubic part of the device, each of which is covered with a light metal basket as a holder. The air containing the dust is drawn into the machine by a centrifugal suction fan through the air transfer pipes, and the dust particles remain on the outside of the filters and the purified air passes through the upper part of the chamber. Finally, the pollution-free air is removed through the suction and returned to the environment.

High pressure air (6-8 bar) is used to clean the filter bag cloths. In this way, the compressed air stored by the compressor stored in the collector tank is blown through the piping network in the inner part of the fabrics, respectively, by the sudden opening and closing of the solenoid valves, which are controlled by the PLC switchboard. . With each sneeze of compressed air inside each row of baskets, the dust around the fabrics is cleared and falls into the funnel and is removed from the funnel by the rotary valve, thus the fabrics take turns during the interval. They are cleared at the scheduled time. This makes it possible to operate the device without interruption.

Parts and Components:

Body: includes a rectangular or cylindrical cube housing with a funnel and metal bases and a roof made of ST37 iron sheet.

Metal baskets: to hold bags and hang fabrics inside the compartment. It is better to make these baskets from wire mesh.

Filter bags: for air purification and dust separation, which can be made of polypropylene, polyester, poly acrylo, depending on operating conditions such as operating temperature, humidity and vapor, and particle size. nitrile), glass fiber and…. For example, in the manufacture of filter bags for lime and cement kilns, heat-resistant fabrics should be used.

Venturi funnel: to increase the effect of jet pulse and prevent the return of sneezing air inside the bags to the upper space of the bags. In fact, the presence of horns increases the efficiency of the jet pulse and makes the filters clean better.

Air Compressor: Supplying compressed air to blow compressed air into the bags by solenoid valve and cleaning filter cloths

Compressed air capsule: Supply of compressed air and its distribution of solenoid valves

Solenoid valve: for automatic opening and closing and blowing compressed air pulse inside the bags and cleaning cloths

PLC switchboard: for planning and scheduling the opening and closing of solenoid valves. This system helps to automate the Dust Collector device and program according to the amount of dust entering the device.

Locke vacuum valves (Rotary valve): for removing dust from the Dust Collector funnel and the arrival of outside air into the hopper. If you do not use a rotary valve, emptying the funnel will be difficult and out of control. This is because the operator will experience a sudden drop of material into the hopper or no material falling down (due to the strong suction of the centrifuge sucker).

Centrifugal suction fan: to collect and direct polluted air and airborne particles and dust into the filter bag chamber

Usage and applications of Dust Collectors:

- MDF and chipboard factories

- Woodcutter

- Electrical insulation factories

- Ore crushing and milling units and chemicals

- Rotary kiln for gypsum, cement, lime, dolomite

- Rotary melting furnace for ingots of zinc, copper, cast iron, lead

Frequently asked questions

When two or more cyclones are parallel to each other, it is called multi-cyclone. In this case, the air passing through the ducts is divided between several cyclones and after passing through the cyclones and separating the major part of the dust, it rejoins and moves towards the filter bag and suction fan.

In the industrial (automatic) bag filter, the bags are constantly cleaned by compressed air and jet pulses, but in the traditional bag filter, the suction should be turned off and the bags must be shaken manually.

Also, in the industrial filter bag, the suction fan is after the filters and no dust gets trapped inside the suction fan. However in the traditional filter, the suction fan is located between the dust release area and the filters, and the dust is blown into the bags after passing through the suction fan.

It depends on the humidity and passing gases as well as the working temperature of the device. Corrosive gases such as SO2 and SO3, water vapor, and acid vapors cause rotting of the internal body of the device. High temperatures will burn the bags. But in places like sawmills and chipboard and MDF factories where there is no water vapor, acid gases, and high temperature, the life of the bag filter may be tens of years.

It Depends on the type and material of the bag. For example, polyester is very weak against acid gases and, polypropylene is very resistant.

- Prevention of environmental pollution

- Prevention of damage to personnel and production line operators due to dust

- Prevention of wastage of materials

The size and capacity of the filter should be suitable for the needs. Also, according to the standard of the Iranian Environmental Organization, depending on the type of activity, the dust coming out of the exhaust fan should be within the range approved by the organization.

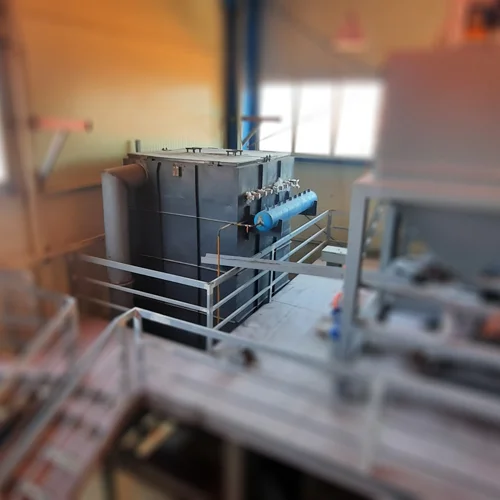

Some built-in Dust Collector

Hamun Industrial Group

Dust Collector 81 phosphate bags

Dust Collector 100 bags of sedimentary calcium carbonate

Dust Collector 160 bags

Dust Collector 160 bags

Dust Collector 198 iron melting bag

Dust Collector 256 bags

Dust Collector 336 bags

Some of Hamon Industrial Group's projects

Useful links

Machine manufacturing