WHAT IS A ROTARY DRYER ?

Rotary dryer is one of the most widely used dryers that are used to dry various chemicals, minerals, food. These dryers are based on rotary ovens designed and upgraded by English Ransom in 1885. These dryers are composed of metal pipes with a diameter of 60 to 300 cm and a length of 6 to 24 meters, which are placed on rollers and rotate with a gentle slope around the horizontal ridge.

Agricultural and vegetable wastes such as beet pulp, sugarcane pulp, tomato pulp and citrus peel are among the plant and agricultural materials that are used by rotary dryers to produce animal feed. In the chemical industry, rotary dryers are used to dry iron sulfate, manganese carbonate, zinc carbonate, zinc sulfate, etc. Also, in the production of asphalt, a rotary dryer is used to dry and heat the sand in the asphalt.

ROTARY STEEL DRYER

Rotary steel dryer is used in some cases that require drying of chemicals or food. For example, in the case of drying chemicals such as zinc sulfate or crystalline manganese that have an acidic pH, the presence of acidic wet material with iron metal, causes corrosion of the inner surface of the dryer, wear of the device and most importantly contamination of the material inside the dryer, iron element And their quality and price will decrease. Therefore, in such cases, it is necessary to use a rotary dryer with a steel surface. 304 steel alloys (for food), 310 (for materials that need to be dried or baked at high temperatures, 316 (for chemicals) are used in the manufacture of steel dryers.

How the rotary dryer works

Drying of materials in rotary dryers is done by the presence of wet materials with hot and dry air produced by a burner or gas heater or diesel burner. Materials from the upper part of the dryer After the wet material enters the rotary dryer, the materials are exposed to hot air produced by the burner and dry by rotating the dryer tube with the help of gravity and metal blades angled downwards. They move and dry along the path in the dryer tube and gradually lose moisture and finally leave the machine. The installation of spoons causes better turning of the material and better stirring and more hot air contact with the material and helps the material to dry faster and better.

In iron-walled dryers, it is possible to increase the temperature of the material up to 250 degrees, and to apply higher temperatures, it will be necessary to use a refractory steel dryer or a refractory wall dryer.

If there is a need to apply indirect heating to the material, heat should be given to the outer body of the dryer tube and after the dryer wall is heated, the material inside the dryer tube should be dried.

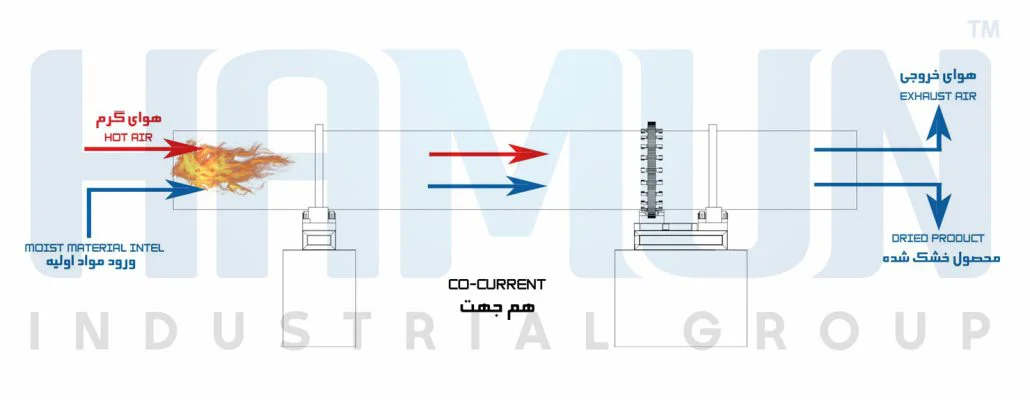

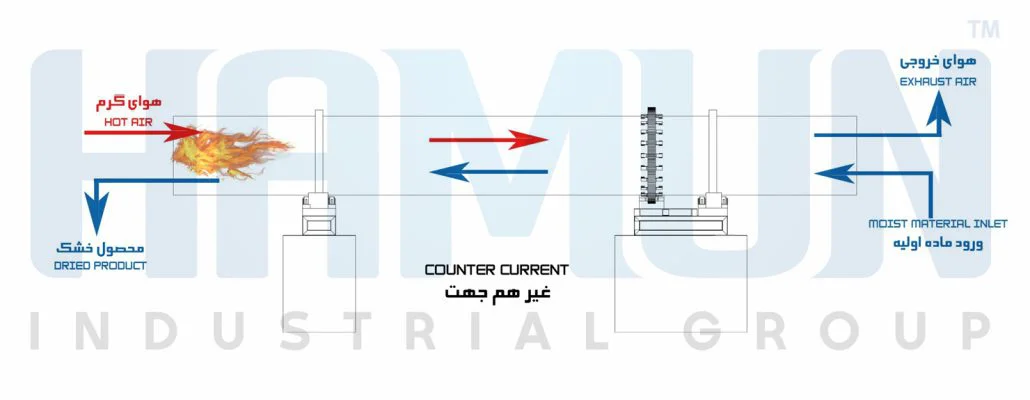

Hot air entering the rotary dryer may enter the dryer either in the same direction or in the opposite direction.

A dust trap or bag filter is used to prevent material wastage and to prevent environmental pollution, and the suction fan will help create airflow in the dryer

Types of rotary dryers in terms of the direction of material and hot air passage

- Co-Current

The direction of passage of material and hot air is the same. In this case, cold and wet materials along with hot air enter the machine from the dryer inlet side and constantly move away from the heat source. This mode is better for when there is no need for complete drying and also when the material is sensitive to temperature and there is a possibility of burning and changing the color or chemical nature of the material. For example, drying bentonite and kaolin will be better in this way due to the sensitivity of these materials to high heat and also due to the fact that there is no need to completely dry these materials. Or, for example, if manganese carbonate is exposed to a temperature of more than 90% Celsius, it will change color from light pink to brown, so it is better to use a rotary dryer to dry it.

Counter-current

The direction of passage of materials and hot air is opposite. In this case, the material enters the machine from the inlet side of the dryer and the burner are installed at the end of the machine. The material is constantly getting closer to the heat source and finally exits the dryer. This type of design is suitable for materials that are not sensitive to heat, and the aim is to dry the materials as much as possible.

For example, to dry soil or zinc concentrate or products that are supposed to be micronized after drying, it is better to dry them with a non-directional rotary dryer so that the humidity reaches less than 0.5%. Because high humidity will disrupt the milling and micronation operations.

Types of dryers in terms of placement angle Rotary dryer with angled tube:

The tube of these dryers has an angle (2-4%) relative to the horizon.

In dryers whose rotating drum is made inclined (with an angle of 2-4%), the lifters are installed without an angle, because the slope of the pipe and gravity will cause the material to move inside the dryer. The advantage of this method is the ease of design and installation of lifters, and the distribution and fall of materials will be done in a better way in the cross-section of the rotating pipe, and the efficiency of energy consumption will be better. The drawback of this method is putting pressure on the trust rollers (stoppers), which increases their wear and tear.

Rotary dryer with no angle and completely horizontal tube

In dryers where the tube is placed on a slope, the lifters are made at an angle to move the material forward. In this method, there is some limitation in the way of connecting the lifters, and it will be more difficult to adjust them. The advantage of this method is the absence of high pressure on the stoppers and less depreciation.

Mixed design:

The pipe has an angle to the horizon, and the lifters are also installed at an angle. Sometimes a combination of these two methods (creating a slope in the pipe and installing the dryers at an angle) is used to pass the materials inside the dryer.

Rotary furnace components

- Rotating dryer tube

- Rotary dryer torch

- Rotary dryer rollers

- Gearbox and electric motor

- Hood

- Chassis

- Gears and pinions or chains

Application of rotary dryer

For drying fruit and vegetable wastes such as:

- Vegetable waste

- Beet

- pulp Sugarcane

- pulp Tomato

- pulp Citrus pulp and …

They are used to producing poultry feed and agricultural fertilizers.

Also in the chemical industry for drying:

- Iron sulfate

- Manganese

- carbonate Zinc

- sulfate and …

In the production of asphalt, a rotary dryer is used to dry and heat the sand in the asphalt

Hamun Industrial Group, manufacturer of dryers and rotary kilns, with brilliant history and experience in the production of chemicals and minerals and many years of experience in the manufacture of dryers, ready to consult, design and manufacture dryers and furnaces Rotary for domestic and foreign manufacturers and craftsmen.