What is calcined bauxite?

Calcined bauxite with chemical formula Al2O3 is a widely used product that has many applications in the manufacturing building blocks, extraction, and casting of iron and cast iron, and production of refractory materials and bricks.

Bauxite is sedimentary rock and contains aluminum with a grade of more than 45%. The bauxite ore is used to produce aluminum metal, and often contains gallium deposition, so it is also a source of gallium. The industrial extraction of aluminum from bauxite is performed using the Bayer process.

Calcined bauxite is produced by calcination of bauxite ore at 900 to 1700 °C by a rotary kiln or multiple hearth furnace kiln (known as a vertical calciner). Applying temperatures about 1650 to 1700 °C leads to the sintering or frittage.

Consumption of calcined bauxite in fire-resistant materials such as alumina mortars and refractory bricks increases the compressive strength as well as shock resistance of the refractory bricks and lead to more product sales due to better quality.

Calcined bauxite production method

Calcined bauxite is produced by heating and sintering bauxite ore in a rotary kiln at 900 to 1700 °C. Depending on the application of the product, the applied calcining temperature is various. For example, for application in the production of aluminum sulfate, a temperature of 900 °C is suitable, and for application in the production of steel and cast iron, a temperature about 1450 °C is required.

To produce refractory materials and sintering, the furnace temperature must be raised to 1700 °C. Due to the creation of dust in the rotary kilns, in order to prevent material waste and environmental pollution, it is necessary to install a dust collector cyclone and a filter bag on the rotary kiln.

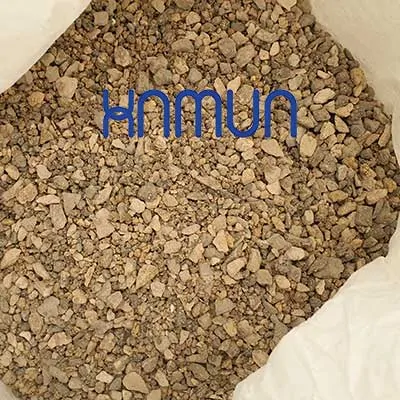

Then, the molten materials are passed through a rotary cooler and after grinding and granulation are ready, in different particles size, for sale.

Calcined bauxite is sold in packages of 25 to 1000 kg. Powdered calcined bauxite with 1000 mesh is used to produce light bricks and Leca.

Uses and applications of calcined bauxite

- Production of refractory soil, materials, and bricks

- Used to prevent slippery roads and passages

- Production of sandpaper and abrasive plate

- Iron mining and extraction, cast iron and foundry industries

- Production of aluminum sulfate and aluminum compounds such as hydroxide and aluminum oxide

Hamun Industrial Group, with its own factory for processing minerals and rotary kilns, as well as micronizing machines, is ready to produce and sell the required calcined bauxite to domestic and foreign manufacturers and industrialists.

- Condition:

- Seeding: Powder to 1000 mesh

- Packaging: 25 to 1000 kg